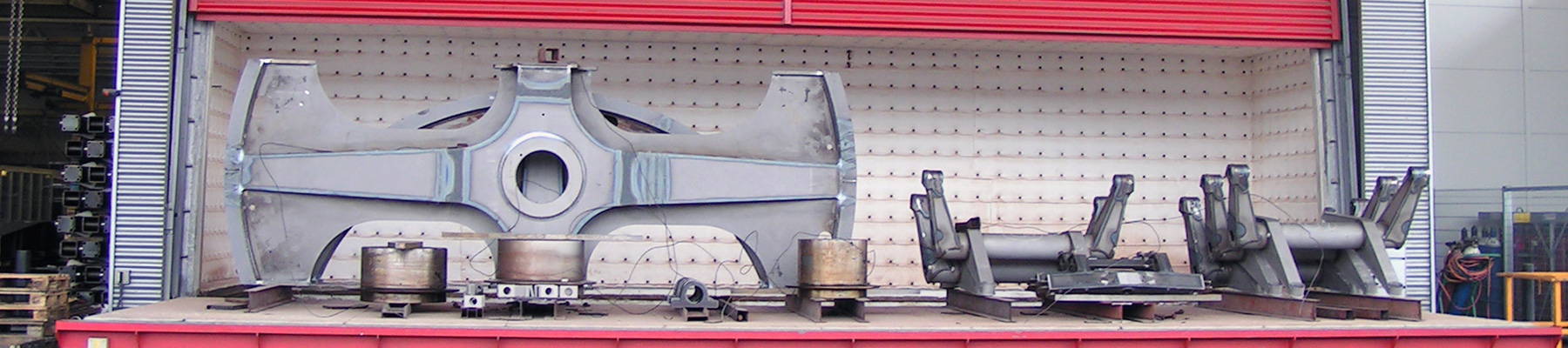

WBHS is using mobile heat-treatment ovens, which enable us to heat-treat large quantities of parts on-site. We are able to provide mobile heat-treatment plants in (almost) any size.

>

economic time factor

Pre-heating – serving controlled heat for construction parts We specialize in these three pre-heating methods.

- Electrical pre-heating with mains current.

- Gas-based / infrared (fully automized)

- Induction-based

Onsite pre-heating – according to desired parameters and the rules of ASME/DIN. Lowers the risk of unwanted deformations caused by uneven cool-downs or tensions caused by the welding process. Heat-treatment takes place at high temperatures without changing the mechanical qualities.

Tension Reduction

Lowers the risk of unwanted deformations caused by uneven cool-downs or tensions caused by the welding process. Heat-treatment takes place at high temperatures without changing the mechanical qualities.

Re-Cristallization Heat Treatment

Normalizes a change in structure caused by cold reshaping which increases tensile strength and hardness while at the same time lowering glutinousness and formability. Temperatures range from 500 to 700 degrees Celsius, cooling-down temperature must be sufficiently low.

Solution Heat-Treatment

By warming an alloy at high temperature, all unwanted elements get seperated at an increased speed.

For On-Site Heat Treatments we use these technologies as required:

- Electric heat treament (mains current)

- Electric heat treament (high voltage)

- Gas-based (high-speed burners)

- Mobile Heat-Treatment Ovens

- Induction-based